Introduction

In today’s fast-moving manufacturing world, precision, speed, and cost-efficiency matter more than ever. One essential component that makes this possible is the press tool. Whether you’re working in automotive manufacturing, appliance production, aerospace, or metal fabrication, a press tool plays a critical role in shaping raw materials into accurate, repeatable parts. This article explores what a press tool is, how it works, the different types available, and why it remains one of the most valuable assets in industrial production.

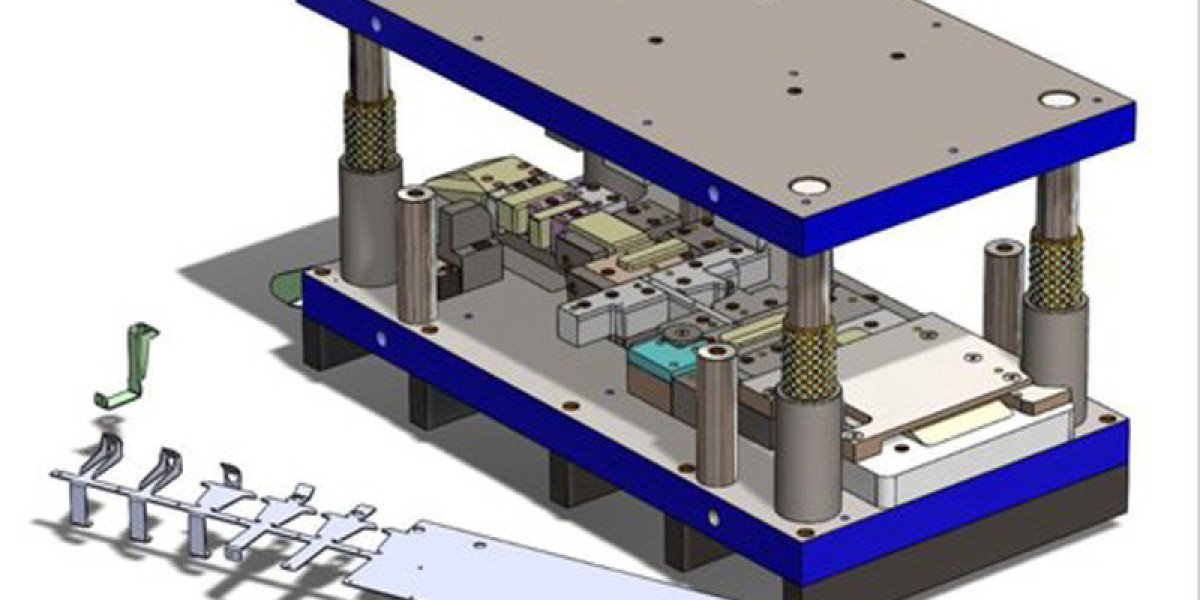

What Is a Press Tool

A press tool is a specially designed device used with a press machine to modify sheet metal through cutting, bending, forming, punching, or drawing. The metal sheet is placed between the punch and die, and when force is applied by the press machine, the material takes the desired shape. Because a press tool can produce uniform parts at high speed, it has become a backbone technology in mass production industries.

While the concept sounds simple, designing a press tool requires engineering precision. Factors such as material thickness, metal properties, tolerance levels, and production volume all influence the tool’s shape and structure.

Key Components of a Press Tool

Although there are many designs, most press tools include a few common components:

Punch – The element that applies force and shapes the material.

Die – The receiving part that defines the final shape.

Stripper Plate – Removes metal from the punch after the cutting or forming operation.

Make sure the punch and die are aligned by using guide pillars and bushings.Shank or Clamping Section – Used to mount the tool in the press machine.

Each part must be manufactured with high accuracy to ensure consistent performance, long tool life, and minimal downtime.

Types of Press Tools

A major reason the press tool is so widely used is its versatility. Different types are designed to perform specific operations:

Blanking Tool

Used to cut out a flat piece from sheet metal, which later becomes a finished component. The blank itself is the required product.

Piercing Tool

This tool punches holes or shapes inside a metal sheet. The removed part is scrap, while the remaining sheet is the product.

Bending Tool

A press tool used for bending transforms flat sheets into angled or curved forms, as seen in brackets and enclosures.

Forming Tool

Forming tools stretch or deform metal into complex shapes without cutting it. This is common in automotive body parts.

Drawing Tool

Used to create cup-shaped or hollow components such as cans, kitchen sinks, and fuel tanks.

Progressive Tool

A highly advanced press tool that performs multiple operations in a single stroke sequence. The metal strip moves step-by-step, and different actions occur at each station. This makes it ideal for high-volume mass production.

Industries That Rely on Press Tools

You’ll find the press tool almost everywhere manufacturing is present. Major users include:

Automotive – body panels, brackets, engine components

Aerospace – lightweight precision parts

Electronics – connectors, terminals, cases

Appliances – housings, panels, frames

Construction – fittings, frames, structural parts

Because of their accuracy and repeatability, press tools help industries maintain strict quality standards while controlling costs.

Benefits of Using a Press Tool

A modern press tool offers several advantages that make it indispensable:

High Production Efficiency

Once installed, a press tool can produce thousands—even millions—of identical parts with minimal adjustment.

Superior Accuracy

Precision design ensures every piece matches exact specifications, reducing rework and waste.

Cost-Effective for Mass Production

Although initial investment may be high, long-term production costs drop significantly due to speed and repeatability.

Consistent Quality

Because the process is mechanical and controlled, variability is extremely low.

Versatility

A press tool can be customized to suit almost any metal forming need.

Material Selection for Press Tools

The life and performance of a press tool depend greatly on the material used to build it. Tool steels like D2, H13, and carbide are common because they resist wear, heat, and impact. For high-stress applications, hard coatings such as nitriding or titanium nitride may be added to extend durability.

Design Considerations

Designing a reliable press tool requires careful planning. Engineers must evaluate:

Sheet metal thickness and ductility

Required tolerance levels

Expected production volume

Tool maintenance requirements

Press machine capacity

Ignoring these factors can lead to tool failure, product defects, or excessive downtime.

Maintenance: A Key to Long Tool Life

Even the best press tool requires regular maintenance to perform optimally. Common practices include:

Cleaning and lubrication

Checking alignment

Inspecting for wear and cracks

Re-sharpening cutting edges

Replacing damaged components

Preventive maintenance not only extends tool life but also prevents costly production interruptions.

The Future of Press Tools

As manufacturing evolves, so does the press tool. Today, computer-aided design and simulation allow engineers to predict performance before fabrication. Automation and robotics are increasingly being integrated into press operations, improving speed and worker safety. Advanced materials and coatings are also helping tools withstand higher loads and longer production runs.

Sustainability is another emerging trend. By optimizing tool design, manufacturers can reduce scrap waste and energy consumption—benefiting both the environment and profitability.

Conclusion

The press tool may not always be visible on the factory floor, but its impact is undeniable. From the car you drive to the appliances in your home, thousands of everyday products begin their life shaped by a press tool. Its ability to combine accuracy, speed, and cost-efficiency makes it a cornerstone of modern manufacturing.

Whether you’re a student of engineering, a manufacturing professional, or simply curious about industrial processes, understanding the role of the press tool gives you insight into how raw sheet metal becomes precise, functional components that power our world.

See more our web site:visit here